We’ve all seen them. Weeds. Along your concrete driveway expansion joints. Many, if not most, people will just remove the weeds only for them to grow back as soon as it rains. So, why do weeds grow along these lines? Apparently just a little bit of dirt that makes its way into these gaps is enough to cause weeds to grow. I’ve had enough of these weeds growing every year so here’s my attempt to resolve this annoyance once and for all.

Remove Weeds

To remove weeds, you can use an oscillating tool, a small reciprocating saw, or even a utility knife or flathead screwdriver. Since I like doing things the quick and easy way, I use an angle grinder with a wire wheel.

To prevent kickback and potentially hurting yourself, stand perpendicular to the direction the wire wheel rotates.

If you need to enlarge some gaps or smoothen them out, you can use an angle grinder with a diamond blade.

Fill Gaps

Now, my driveway has gaps that are small (1/4″), medium (1/2″) and wide (3/4″ – 1″) in width and the depths range from 1/4″ to maybe 3″ deep. The small and shallow gaps are usually not a problem.

At first, I thought about filling some small gaps with Sakrete Concrete Crack Filler since the driveway is made of concrete.

Concrete Crack Filler

I tried this on a small gap and product was very easy to apply and it settles nicely producing a nice bead.

However, it turns out you shouldn’t do that because apparently those gaps – called expansion joints or control joints – are by design so filling these gaps with concrete defeats their purpose. Concrete Crack Filler is good, however, if you do have a thin, natural crack (not expansion joint) because it hardens just like concrete.

Concrete Filler and Sealant

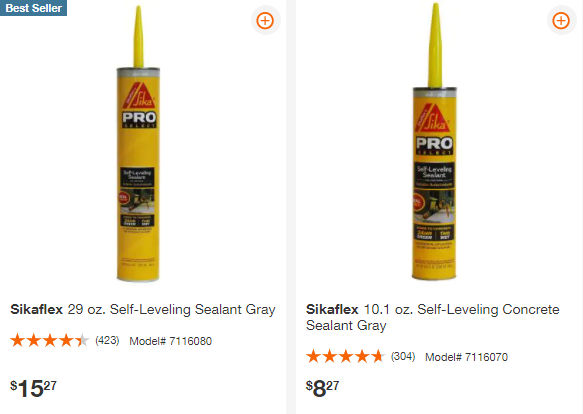

For horizontal surfaces or slightly sloped surfaces like your driveway, use Sikaflex Self-Leveling Sealant.

Foam

Now, for some of the larger gaps, it would be too expensive and wasteful to fill them with sealant. For those, I decided to use a foam gap filler.

Apply Foam

This stuff really does expand and is pretty sticky when wet. It’s great for filling large gaps. Of course, you’ll need to trim the foam in order to apply sealant. This can be done with a utility knife, a mini reciprocating saw, or, better yet, an oscillating tool.

I cut away the foam a little bit below the surface of the concrete to allow for a layer of sealant.

Apply Sealant

At first I bought the 10 oz sealant but because I wanted to seal all joints, I got the 28 oz sealant (cheaper) and a 29 oz caulking gun. As you can see below, the sealant self levels resulting in a nice, smooth finish.

Had I gone with non self-leveling sealant like Sikaflex Construction Sealant

then the result would look like this:

You could try to smoothen it out using a taping knife by why bother. This type of sealant is better for vertical surfaces.

Now, if you don’t like the look of a gray joint, you can color your driveway with Rustoleum Epoxy or Behr Granite Grip and the entire driveway will be the same color.

Sand

You can also sprinkle sand on the sealant to prevent debris from sticking to it while it dries.